Electric vehicle batteries and graphene: a future that is already a reality, in some cases. Here is how and why this innovative material is making its mark on the electric mobility industry, but not only.

“Graphene, as an allotrope of carbon, possesses highly efficient and landmark properties and characteristics in various fields. “*

Because of its characteristics and potential, the EU announced in 2013 an ultra-decade investment plan ( Graphene Flagship project) to develop graphene-based technologies.

The project has brought together nearly 170 academic and industrial partners in 22 countries to foster commercial applications.

Sommario

- 1 Graphene, what is it?

- 2 An outstanding material

- 3 The future of energy storage

- 4 Graphene, what the studies say

- 5 Industrial developments of graphene

- 6 Batteries for electric vehicles, growing demand

- 7 Applications of Graphene-based Metal-Air Batteries.

- 8 Challenges and future developments

- 9 About Fastbrain and why to choose it

- 10 Contact us for a free consultation

Graphene, what is it?

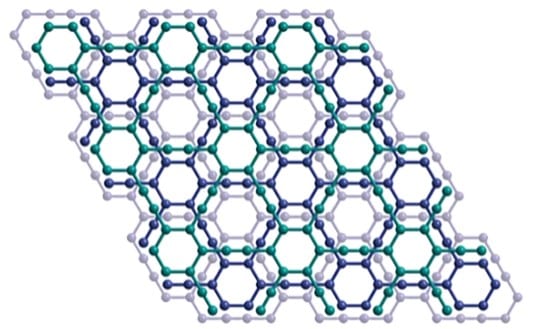

Invented in 2004 by Andre Geim and Konstantin Novoselov, researchers at the University of Manchester and winners of the 2010 Nobel Prize in Physics, graphene is a nanomaterial formed by a single layer of carbon atoms in the form of a hexagonal lattice.

A million times thinner than a human hair, it is the thinnest object ever invented, but at the same time it is among the strongest, about 200 times stronger than steel, and it is also an excellent thermal conductor, with a faster rate than most other materials. *

This innovative material is still undergoing various tests and research, affecting the world’s economies.

But how can it improve battery production for electric vehicles?

Let’s find out its peculiarities and strengths.

An outstanding material

Graphene is an exceptional material with several positive properties that make it the subject of innovative research and applications. Here are three positive aspects:

Extraordinary electrical conductivity:

Graphene is known for its exceptional electrical conductivity. Its two-dimensional carbon sheet structure enables graphene to transport electrons at an extremely high rate (6 times faster than copper).

A feature that makes it an ideal candidate for applications in electronics, as a semiconductor, and in high-efficiency batteries.

High thermal conductivity:

In addition to its excellent electrical conductivity, graphene also exhibits high thermal conductivity.

The ability to dissipate heat efficiently makes it valuable in applications such as thermal devices, cooling systems, and advanced composite materials.

Robustness and mechanical strength:

Extremely robust despite its thin structure, graphene has mechanical strength, which exceeds that of many conventional materials; it also makes it suitable for applications where light weight and strength are crucial, such as in advanced composites, wear-resistant coatings, and aerospace applications.

These positive aspects are supported by research published in reputable scientific journals, demonstrating its revolutionary potential in various technological and scientific fields.

The future of energy storage

Graphene, as mentioned, consists of a sheet of pure carbon with a single layer of atoms placed in a lattice fashion to form a regular hexagon. It has a much longer service life than lithium, and its properties are similar to carbon; it is extremely durable and five times lighter than aluminum.

It is far easier to synthesize in the laboratory, and batteries made from this material can last quite a bit longer than lithium batteries.

A real industry breakthrough, “game changer” and probably turning point in the e-car industry.

Power and effectiveness are the two key elements that the tests are focusing on. The positive outcomes so far bode well for their near-term use in energy storage, resulting in longer-lasting, higher-performance batteries.

A benefit to the environment as well, given the longer wear and tear times. Also benefiting is the charging itself, which is much shorter than that of lithium batteries.

These aspects make graphene batteries perfect for various applications, such as in materials science and particularly for electric cars; fast charging would eliminate overnight charging times with lower energy consumption and charging frequency.

A technology that is also applicable to products such as smartphones (rechargeable in five minutes), flexible displays, solar panels, seawater desalinators, smartwatches and other gadgets that require electric charging.

Graphene, what the studies say

The study, “Synthesis and characterization of graphene and its composites for Lithium-Ion battery applications: A comprehensive review,” points out that in recent years, the demand for high-performance rechargeable lithium-ion batteries has grown significantly, focusing on improving state-of-the-art electrically conductive materials.

Graphene and materials based on it have been the subject of further study and research, now recognized as high-performance materials for electroconductivity.

Graphene was created from two-dimensional carbon and exhibits outstanding electrical conductivity, excellent intrinsic electron mobility, enhanced mechanical strength, photosensitive transparency, catalytic activity, and chemical stability

This material and its compounds are presented as “materials of interest” for various energy storage technologies, particularly in lithium batteries.

Its outstanding properties, such as its huge surface area, high electrical conductivity, and intrinsic electron mobility, make it ideal for improving battery performance.

The article mentions several research studies that have used graphene in combination with other materials to improve the capacity, charge/discharge rate, and cyclic stability of lithium batteries.

Since its creation, graphene has attracted great interest because of its extraordinary properties, including transparency, lightness, flexibility and strength.

Yet, large-scale production is limited due to high costs. Various synthetic techniques have been used to produce high-quality graphene, but the challenge remains in optimizing production costs.

Nevertheless, graphene remains a promising candidate for improving the performance of lithium batteries and contributing to the development of advanced energy storage technologies.

Industrial developments of graphene

A bulletproof graphene battery

Nanotech Energy, in collaboration with Voltaplex, has developed a graphene battery that is bulletproof and does not burn at high temperatures.

The need to produce a safer storage system stems from observation of the frequency with which, at high temperatures, batteries tend to catch fire.

The Consumer Product Safety Commission in 2018 in the US reported more than 25,000 incidents in which batteries overheated to the point of causing fires.

Early tests have seen graphene used in a new lithium-ion battery, stressing even above 180° without catching fire.

Other evidence, which has gone viral on the web, the firing of a bullet that despite passing through the battery at 900 m/s does not cause sparks.

Curtis Collar, Chief Sales of Nanotech Energy writes:

“We have read several times about huge fires caused by cheap and poor quality batteries. Their devastating effects have caused significant losses to people: sometimes their homes, sometimes their businesses. In the worst cases even their lives. With our battery, we say enough of this.”

Everything would seem to be ready, then, for an imminent market launch.

Graphene batteries on the GAC SUV

GAC, a renowned Chinese automaker, has officially announced the upcoming launch of its next-generation electric SUV, Aion V.

What makes this vehicle unique is the adoption of a graphene battery, enabling an extraordinary charging speed from 0% to 80% in just 8 minutes. The Aion V successfully passed demonstration tests, reaching a peak charging power of 481 kW.

The SUV will be available in two versions, 3C and 6C, with the 6C able to support ultra-rapid charging, promising an outstanding 1,000 km range according to the NEDC standard. During testing, it was found that the car received 35.1 kWh in just 4 minutes, highlighting the efficiency of the graphene battery.

GAC has consolidated its expertise in the field of graphene since 2014, saying it can apply this technology not only to lithium-ion batteries but also to lithium sulfur batteries and supercapacitors.

Yet, implementation on these will have to wait. GAC made good on its promises made earlier this year regarding the timely introduction of this revolutionary graphene battery, starting mass production without yet providing detailed data on capacity and maximum charging speed, aspects in which graphene excels.

Batteries for electric vehicles, growing demand

A recent report by IEA (The International Energy Agency) analyzes the state of demand for electric vehicle batteries.

In particular, it is noted that the demand for lithium batteries for electric vehicles (EVs) increased by about 65 percent to 550 GWh in 2022 from 330 GWh in 2021. This increase is mainly due to the growth of electric car sales, with new registrations increasing by 55 percent in 2022 compared to 2021.

In China, demand for vehicle batteries grew more than 70 percent, while sales of electric cars increased by80 percent in 2022 compared to 2021.

In the U.S., demand for vehicle batteries has grown by about80 percent, despite the fact that sales of electric cars increased by only 55 percent in 2022.

The average battery size for electric cars in the United States grew by only 7 percent in 2022, but remains about 40 percent larger than the global average, mainly due to the larger share of SUVs in U.S. electric car sales.

The sale of electric cars

The global trend* shows that sales of battery electric cars (BEVs) and plug-in hybrids (PHEVs) are outpacing sales of hybrid electric vehicles (HEVs ), further increasing the demand for batteries.

Increased demand for batteries impacts the demand for critical materials such as lithium, cobalt, and nickel.

Batteries: diffusion and trends

Lithium-nickel-manganese-cobalt (NMC) battery chemistry remains dominant, with 60 percent market share, followed by lithium iron phosphate (LFP) with about 30 percent, and aluminum cobalt nickel oxide (NCA) with about 8 percent.

LFP batteries are gaining market share, mainly due to the preferences of Chinese manufacturers. About 95 percent of LFP batteries for light electric vehicles (LDVs) are for vehicles produced in China. Tesla, which accounts for 15 percent of LFP battery demand, has increased its share from 20 percent in 2021 to 30 percent in 2022.

LFP batteries differ from other chemistries by using iron and phosphorus instead of nickel, manganese, and cobalt. Nevertheless, LFP batteries have a lower energy density than NMCs and contain phosphorus, an element also used in food production. If all batteries were LFP, they could account for nearly 1 percent of current global agricultural phosphorus use.

Alternatives to lithium batteries are emerging, such as sodium-ion (Na-ion) batteries, which are cheaper and do not require critical materials. Na-ion batteries developed by China’s CATL are estimated to cost 30 percent less than LFP batteries, but have a lower energy density. However, Na-ions might be suitable for urban vehicles or stationary storage.

Prices of critical materials can influence the choice of battery chemistry. Variation in price and availability of critical materials may explain the development of battery chemistries in recent years. The use of nickel in NMC batteries has led to a preference for lower proportions of nickel (NMC622 and NMC811) due to the rising price of nickel in 2022.

Lithium carbonate prices have increased over the past two years, reaching six times the 2015-2020 average in early 2023. While lithium prices have fallen by 20 percent in the first three months of 2023, they could translate into lower battery prices if the trend persists.

Prices: China has the lowest

The effect of the increase in battery material prices is differentiated among the various chemistries, with a more pronounced increase for LFP batteries. However, despite rising prices, LFP batteries remain less expensive than NCA and NMC per unit of energy capacity.

Battery prices also vary among regions, with China having the lowest prices on average. China is the leading producer of bacterial cells and cathodes, which contributes to the global price disparity. Continued decreases in battery pack production costs are expected in the future, according to Bloomberg New Energy Finance (BNEF), with a projected 20 percent reduction in pack production costs by 2025.

In conclusion, the demand for electric vehicle batteries is steadily increasing, driven by the growth of electric car sales.

However, the industry remains at the mercy of changes in battery chemistry preferences, critical material prices, and technological developments. LFP batteries are gaining in popularity, but alternatives such as Na-ion batteries are emerging as cheaper and more sustainable options.

Applications of Graphene-based Metal-Air Batteries.

Flexible metal-air batteries offer advantages in areas such as:

- Flexible multivalent metal-air batteries: The use of graphene in electrodes has improved the performance of multivalent metal-air batteries, such as aluminum and zinc, with excellent flexibility and cyclic stability.

- 2. Graphene-based flexible lithium-air batteries: The use of flexible graphene oxide (GO) paper has improved the efficiency of lithium-air batteries by allowing higher oxygen permeability and maintaining good discharge and charge capacity.

- Metal-air batteries with Graphene: The focus has been on metal-air batteries, such as zinc and lithium batteries, because of their high energy density. The research aims to develop flexible electrodes to ensure flexibility and air permeability.

Performance and utilization

The use of graphene in flexible batteries offers high performance, cyclic stability and flexibility. Graphene-based multivalent batteries show high efficiency even at high currents. In addition, graphene can be used directly as a self-supporting cathode due to its high electrical conductivity.

Challenges and future developments

The deployment of graphene in metal-air batteries is paving the way for sustainable, state-of-the-art solutions in areas such as water purification, water collection, and industrial wastewater treatment.

Further research will aim to optimize performance, reduce costs and further expand the applications of graphene.

About Fastbrain and why to choose it

Fastbrain Engineering Ltd. Certified Partnerof leading Technology Players, including RealWear®, Brother, Lenovo, Synology, Graetz, SiComputer, Canyonoffers customized purchasing solutions tailored to the needs of professionals. It also offers pre- and post-sales support,including operational rental. We are acentralplayer in ICT wholesale distribution and one of the leading players throughout the country in the IT and technology products distribution market. A key feature and competitive advantage is the selection of top brands and leading products in the most popular product categories.

Info:

info@fastbrain.it

| Tel 011.0376.054

Contact us for a free consultation

Resources and sources:

*nanographs.com

*https://www.europarl.europa.eu/topics/it/article/20150603STO62104/grafene-il-materiale-che-cambiera-il-21deg-secolo

https://www.wired.it/article/grafene-materiale-futuro-cose-sapere-applicazioni/ https://www.rigeneriamoterritorio.it/batterie-al-grafene-prospettive-future-energia-sostenibile/

https://nanografi.com/blog/applications-of-graphene-in-metalair-batteries/

https://www.sciencedirect.com/science/article/pii/S1110016823006269

*https://www.iea.org/reports/global-ev-outlook-2023/trends-in-batteries

https://www.repubblica.it/motori/2024/01/11/news/auto_elettrica_arrivano_le_batterie_al_grafene_a_prova_di_proiettile_che_non_si_incendiano_mai-421854603/

https://insideevs.it/news/528201/gac-aion-v-batteria-grafene/